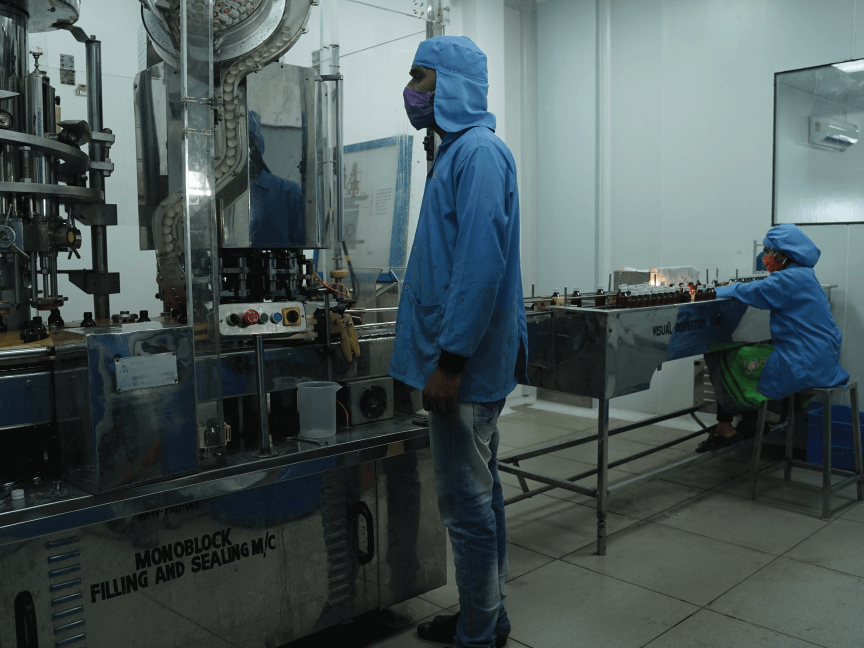

Our facility for

manufacturing

Production

GMP model sophisticated equipments are designed for the operation and in view with the area / class in which they are to be installed. Production are consist of Liquid Section, Ointment Section & Capsules Section. All the equipments are designed and constructed in such a way that the lubricants used will not come in contact with drug product.

| Sr | Particulars | Supplier | Qty in No. |

| Liquid Section | |||

| 1 | Sugar Melting Vessel 1200 Lit. Working Capacity. | Sunrose Engg. | 1 |

| 2 | Manufacturing Vessel 2000 Lit. Working Capacity. | Sunrose Engg. | 1 |

| 3 | In Line Homogeniser | Sunrose Engg. | 1 |

| 4 | Storage Vessels 2000 Lit. Working Capacity. | Sunrose Engg. | 3 |

| 5 | Horizontal Zero Hold Up filter press Centrifugal Pumps. | Sunrose Engg. | 3 |

| 6 | Basket Filter, Zero Hold up with 100-200# basket for Coarse Filtration. | Sunrose Engg. | 1 |

| 7 | 300 Lit. Manufacturing vessel. | Pragati Engg. | 1 |

| 8 | 1000 Lit. Manufacturing Vessel. | Pragati Engg. | 1 |

| 9 | 500 Lit. Manufacturing Vessel. | Pragati Engg. | 1 |

| 10 | Water jet bottles cleaning machine | Anchor Mark | 1 |

| 11 | 8heads automatic rotary volumetric Liquid filling & ROPP/HDPE Cap Sealing machine. | Anchor Mark | 1 |

| 12 | 2 Head Semi Automatic Filling Machine | Ramesh Engg. | 1 |

| 13 | Single Head Cap Sealing Machine | Ramesh Engg. | 1 |

| 14 | Automatic Sticker labelling machine along with Thermal Inkjet Printer. | Maharshi Udyog | 1 |

| 15 | Automatic Carton Over-Printing Machine along with Thermal Inkjet Printer. | Maharshi Udyog | 1 |

| 16 | Packing Conveyor with VFD | Ample Egg. | 1 |

| Capsule Section | |||

| 1 | Manual Capsules Loader & Filling Machine. | 1 | |

| 2 | Manual Capsules counter | Ramesh Engg. | 2 |

| 3 | Packing Conveyor | Ramesh Engg. | 1 |

| Oinment/External Preparation Section | |||

| 1 | Complete Automatic Manufacturing Plant, Capacity 300 kg | Sunrose Engg. | 1 |

| 2 | Semi Automatic Tube Filling Machine | 1 | |

| 3 | Packing Conveyor | Ramesh Engg | 1 |